[ Alto Works ] Durax 15mm Wide Wheel Spacers

I previously discussed wheel spacers and brief positives and negatives of using them. After a few months of riding on non-hubcentric simple wheel spacers, I’d like to strongly recommend that you do not use them.

I discovered that even a few millimeters of off center from the center bore resulted in potentially dangerous wheel wobble at high speed on toll roads. When going triple-digit-kilometer speeds (don’t get excited, that’s only 60 MPH), the right side and particularly the rear right wheel, experienced barely noticeable, but nonetheless worrisome undulating vibrations. I did not experience this wobble at similar speeds on the same road prior to the spacers and on these same wheels/tires.

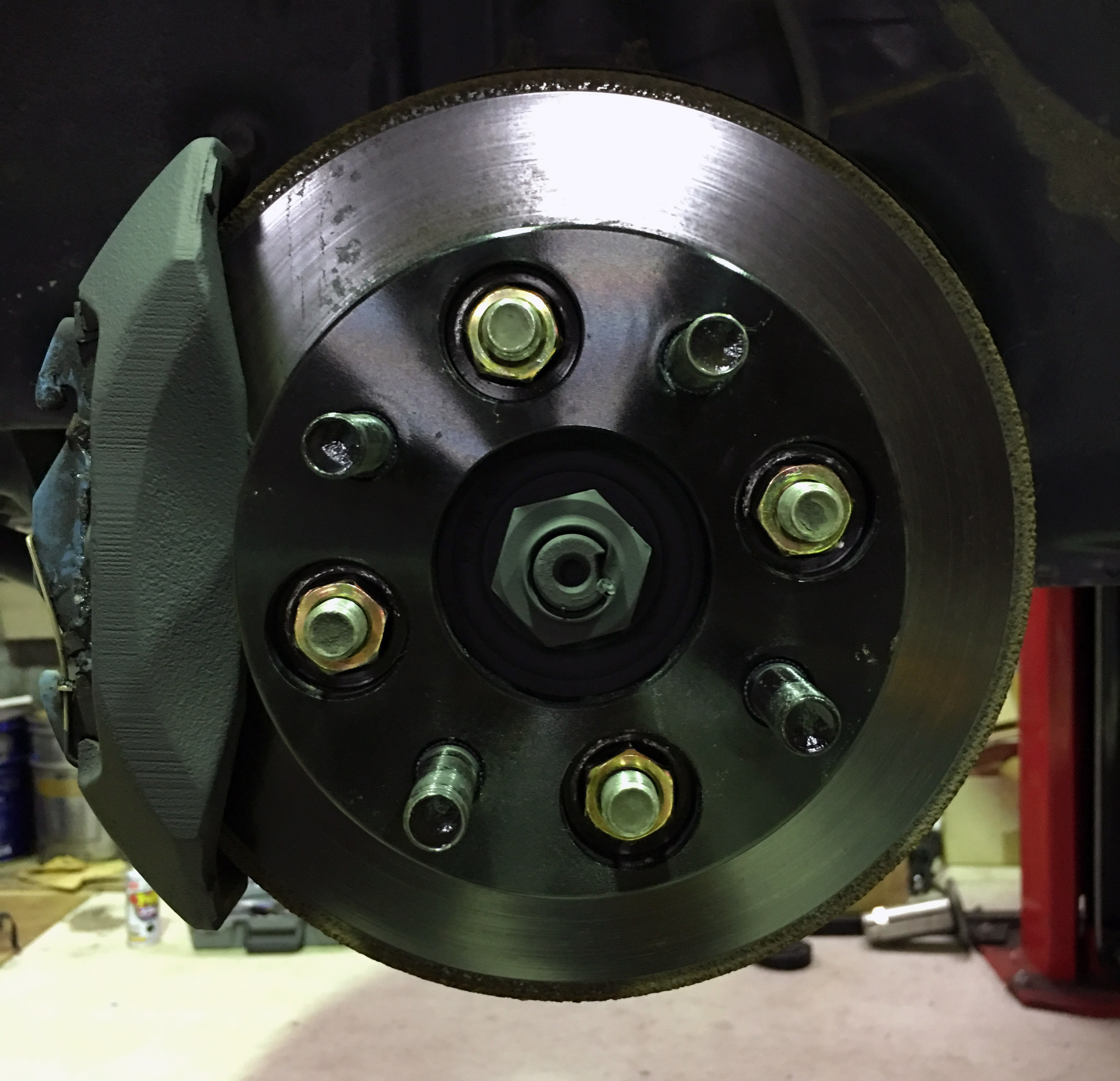

After some measurements, I felt that I could get away with 15mm spacers, but not more without fender rolling. This would effectively give the stock Enkei wheels a +30 spacing. I initially only picked up a set of two as a test to see if I could get away with using them without hitting the fender. For a reasonable sum of around 2800¥ ($26 USD) shipped, I got these Durax 15mm A6061-T6 aluminum spacers with chromium steel wheel studs and carbon steel nuts.

I’ll bet you, as a reader, stopped at “Durax.” One vowel away from Durex. This isn’t the first time I’ve seen Dure.. Durax products in Japan. They are an importer and rebrand company of various Chinese-manufactured car accessories, though generally I have found their products to be surprisingly decent and well-made. For my Alto Works, I’m okay with running cheaper, but decently made parts.

While these are not technically hubcentric spacers, hypocritically contradicting myself from earlier, the tapered spacer lug nuts do help “center” the spacer when tightened down, so it should not be a notable issue. However, I was worried that with only 15mm of spacer, the spacer nuts might stick out past the spacer, preventing use with certain wheels. I was glad to see that the spacer nuts were just thin enough that they sit slightly deeper than the spacer face, allowing the use of most wheels.

Most steel wheels, all multi-pattern wheels, and a few other alloy wheels will not be usable with a 15 or 20mm spacer. The reason is due to the length of the stock studs, which will protrude past the spacer face into the wheel mating surface. Most aftermarket wheels have hallowed-out areas between studs to lighten the wheel, which also allows the remainder stud to clear.

After my spacer install, I soon discovered that the studs on the spacers were quite a bit longer than the stock ones (~33mm compared to ~23mm, respectively). This would necessitate only longer wheel nuts and the stock ones on my Alto Works are just barely long enough.

By “barely long enough,” I really mean exactly that. Upon a test install, the stud just touches and scratches the inside end of the nut. Which means, although it appears to be tightened down, a few micromillimeter gaps could be present between the wheels and the spacers.

This will do for now until I get my second set of spacers in the mail…

Now with the second set received in hand a few days later, I can proceed to install the rear spacers. This time, I took the time to replace all the stock nuts with a set of Suzuki Sport Heptagonal Steel Long Lug Nuts. These should be long enough to not have issue with the extended studs of the spacers.

I’m installing these the good ol’ fashioned way, in my parking lot in front of my house. As always, folks, use a proper torque wrench to ensure the proper torque specs. In my case, the recommended torque for lug nuts is about 110 Nm, equivalent to the typical US recommendation of 80 ft-lbs.

With both fronts and rears installed, I can say quite happily that the lower offset of the spacers have really improved the overall look of the car, pushing out the wheels to just a millimeter past the fender edge. This is absolutely gorgeous from every angle and makes even the stock wheels look pretty darn good, in my opinion.

So how does it fare? Do these 15mm spacers along with the lower stance of the car cause massive fender rubs? I am a bit surprised to say that the front tires have yet to kiss the fender edge, considering there is not much of a wheel gap. However, the rears, with a greater wheel gap but likely softer springs, do actually rub on hard bumps or sudden dips. Although it isn't terrible, it's far from ideal. Which means I have a short task on my list again for next time...

As an added benefit to the wider shoulders, corner turn-in has become marginally more responsive and it feels a bit more planted in wide turns, though it is really hard to say given my old, dry Nankang rubber. (It is harder for me to get consistent feedback.) For the look alone, though, I think this modification was worth it, particularly for my next set of winter wheels that I just picked up...